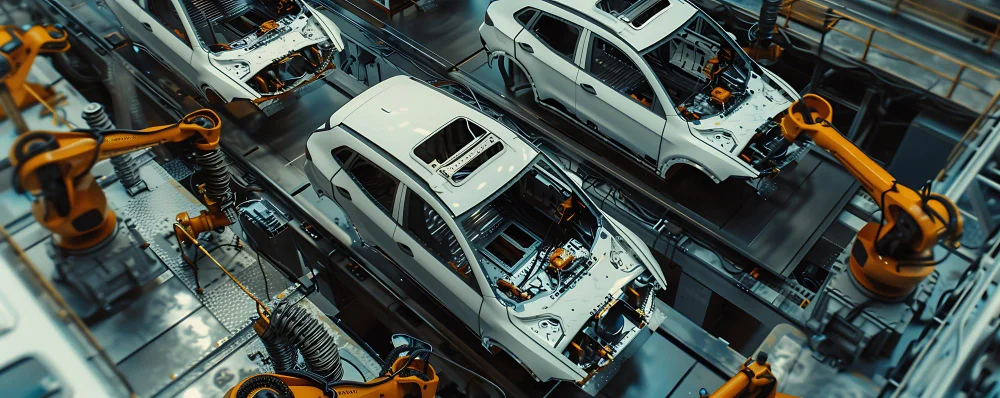

Case Study: Global Automobile Manufacturer

Situation Overview

The United States is one of the most important markets for this global manufacturer of luxury automobiles. It manufactures vehicles in the USA and overseas. For overseas vehicles, the company receives, prepares, and distributes its import vehicles through one of three US distribution centers.

Prior to Birdseye, security at the Distribution Center in the Northeast USA was managed through onsite security guards. Over a 24-hour period, up to 12 guards cycled through the facility over three shifts to manage access through four primary gates (rail, ship, and road), and to monitor the perimeter and interior of the yard.

They had about a dozen older, low-resolution cameras—covering less than 20% of the yard—mainly useful for reviewing incidents after the fact. Vehicle and pedestrian access at the road/truck gate required check-in with a guard. Logs were kept on paper and submitted weekly for archiving, with no real-time management access. Visitors could sometimes enter the yard without proper verification.

Trigger for Change

This company embraces innovation in both products and operations. In 2019, management identified an opportunity to improve security and yard operations at the Northeast DC using technology. Ports and DC yards are high-value targets for crime, so security is vital.

Onsite guards consumed a large budget but offered limited oversight or real-time intelligence. Management wanted technology that could increase efficiency in moving inventory from ships to the dealer network, improve customer satisfaction, and support compliance with security regulations.

The Search for Birdseye

This company embraces innovation in both products and operations. In 2019, management identified an opportunity to improve security and yard operations at the Northeast DC using technology. Ports and DC yards are high-value targets for crime, so security is vital.

Onsite guards consumed a large budget but offered limited oversight or real-time intelligence. Management wanted technology that could increase efficiency in moving inventory from ships to the dealer network, improve customer satisfaction, and support compliance with security regulations.

With Birdseye, we expected to get significant improvement in security and save compared to the budget we were spending on our previous onsite security. What sold us was, once installed, we could get so many operational benefits through Birdseye directly, and by piggy-backing on the live monitoring feeds.

- Distribution Center Manager

Solution Overview

Birdseye implemented 100% real-time monitoring of the 110-acre facility with ~150 cameras, 2-way communication, and other sensors. Gates were equipped with Birdseye ID-Verifi to authorize all visitors before entry/exit.

Remote agents had 24/7/365 access to the private network feed, following company protocols for daily operations and emergencies. Transition from onsite guards to Birdseye took about 3 months, ensuring no disruptions.

Funding came from Birdseye, amortized over the contract, avoiding large upfront costs. The solution reduced security costs by 60% compared to the previous guard contract.

Outcomes

60% Savings on Security

Improved Operational Oversight

Increased Security Coverage

Reduced Security Incidents

Benefits included real-time searchable gate records, elimination of unauthorized visitors, improved decision-making for yard operations, and reduced incidents since early 2020 due to proactive monitoring and deterrence.

Conclusion

Over two years, the partnership with Birdseye delivered the expected security and operational improvements, plus unexpected cost savings and safety gains. The DC team became proactive instead of reactive, boosting operations and credibility with corporate partners and dealers.